質(zhì)量檢測(cè)QUALITY INSPECTION

- Our professional quality inspectors will guarantee samples correct, by using complete measurement equipments inluding checking fixture, CMM Detector. After measurement, they will provide quality report.

設(shè)計(jì)能力ABILITY TO DESIGN

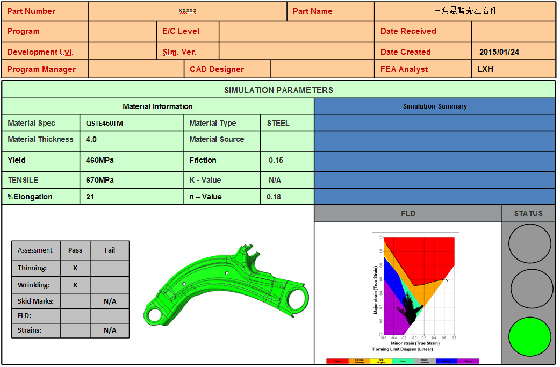

- Our engineering team is comprised by 24 excellent design engineers. among them,5 engineers have over 10 years design experience;5 engineers have over 5 years in CAE simulation analysis.

This team could design about 25 new tools every month. Our fast quoting system could provide accurate and detailed quotation to clients witin 24 hours after receiving project data,also strictly according to clients’ requirements. Auto CAD, UG etc software is used to make 2D and 3D design .

We use individual file and code to classify every project and products.

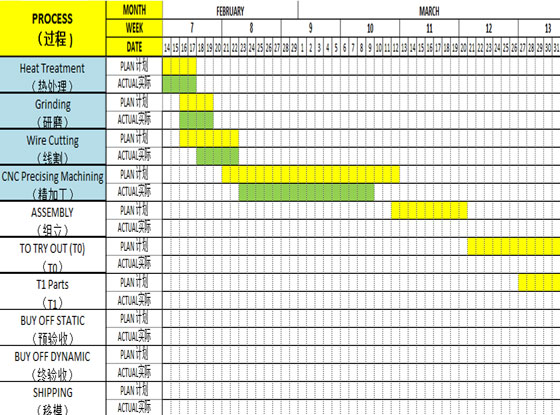

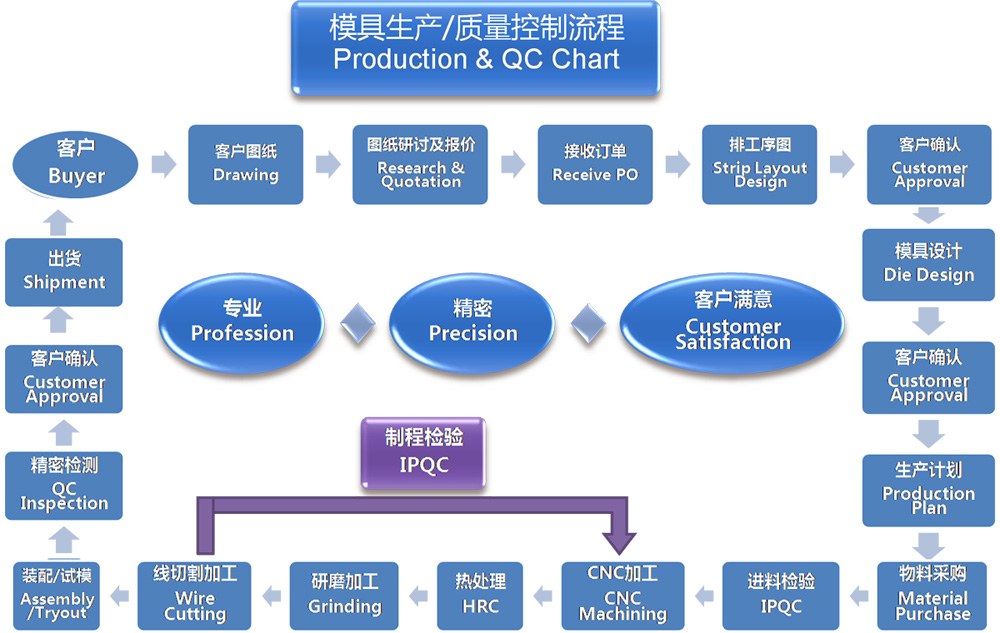

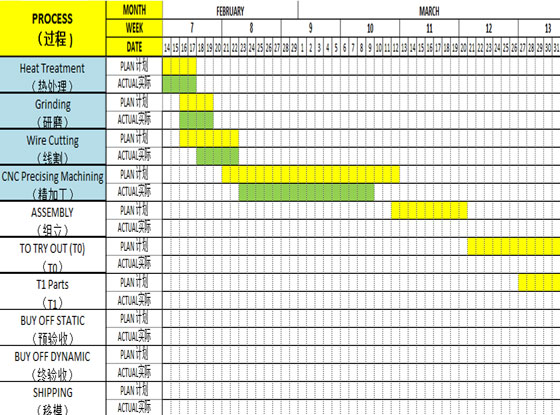

生產(chǎn)進(jìn)度管控PROGRESS CONTROL

- Once PO is placed, we will set up tooling timeline with our customer. Soon after the project kick-off, our program team will have training for the customers’ tooling building standard.

We will submit weekly progress report as per our customers’ requirements.

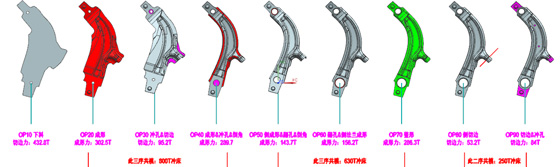

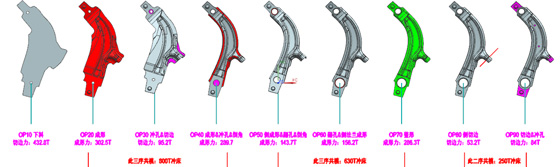

產(chǎn)品成型模擬分版PART FORMING SIMULATION

項(xiàng)目管控

PROGRAM CONTROL